Budget-friendly Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Budget-friendly Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Blog Article

Unlocking the Tricks to Effective Lift Fixes: Specialist Insights Disclosed

In the realm of lift repair work and maintenance, discovering the techniques that lead to effective and efficient service belongs to decoding an intricate puzzle. Professional understandings function as the assisting light with the labyrinth of challenges encountered by upkeep experts in the vertical transportation sector. By diving into the depths of aggressive approaches, fixing methods, and the continuous search of ability improvement, the path to elevating upkeep criteria exposes itself. As we begin on this journey to debunk the tricks behind streamlined lift repairs, a globe of possibilities arises, guaranteeing a future where downtime is reduced, safety is focused on, and operational quality becomes the standard.

Typical Lift Repair Work Obstacles

Another prevalent challenge in lift repairs is the lack of proper maintenance records. Without exact maintenance documents, fixing specialists may have a hard time to identify problems successfully or expect possible problems. This can cause longer repair times and boosted prices as technicians work to troubleshoot concerns without historical information to lead them.

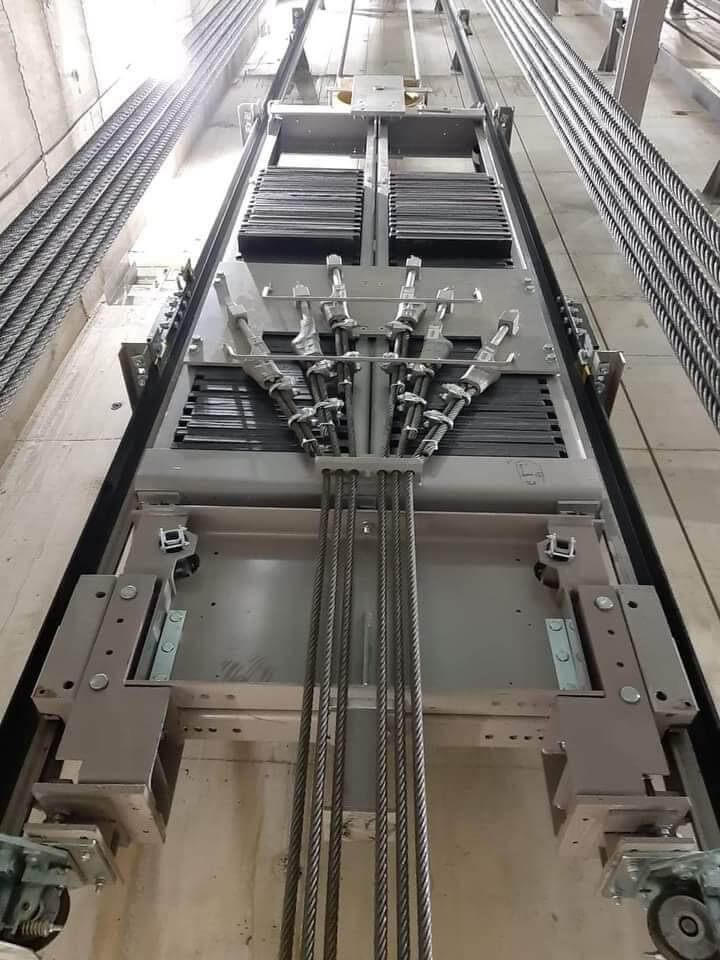

Additionally, accessibility issues within lift shafts can present substantial obstacles throughout repairs. Limited area, unpleasant angles, and intricate equipment can make it difficult for technicians to get to the essential parts for repair, prolonging the total repair procedure - Lift Maintenance Repair. By attending to these typical difficulties proactively, lift repair work professionals can improve operational effectiveness and ensure the smooth performance of vertical transport systems

Proactive Upkeep Methods

Executing aggressive maintenance methods is paramount for making certain the longevity and optimum performance of lift systems. By embracing an aggressive method to upkeep, building supervisors and lift upkeep teams can attend to potential problems prior to they rise into expensive fixings or downtime. One efficient approach is to establish a routine upkeep timetable that includes thorough assessments, lubrication of relocating components, and testing of safety functions.

Moreover, buying training programs for upkeep team can boost their abilities in recognizing possible concerns and executing preventive maintenance tasks effectively - Lift Maintenance Repair. By empowering maintenance teams with the knowledge and devices required to proactively keep lift systems, structure proprietors can lessen disturbances, prolong the life expectancy of their lifts, and make sure a risk-free and trustworthy upright transport experience for passengers

Fixing Methods

Efficient repairing techniques are crucial for quickly recognizing and fixing issues with lift systems to lessen downtime and guarantee optimum performance. One efficient strategy is to start with a detailed visual assessment of the lift parts, inspecting for any kind of visible indicators of damage, misalignment, or check my site wear.

Enhancing Repair Skills

Enhancing proficiency in lift system fixings is a fundamental facet of guaranteeing optimal performance and reducing functional interruptions. Elevator professionals should consistently work on developing their fixing skills to meet the demands of modern-day lift systems.

Furthermore, staying upgraded with the most recent improvements in lift modern technology is important for service technicians aiming to enhance their repair work skills. This includes proactively inquiring about new components, software application updates, and upkeep methods to properly diagnose and rectify problems. By investing effort and time into constant discovering and practical experience, elevator technicians can substantially improve their fixing expertises and add to the reliable performance of lift systems.

Raising Upkeep Specifications

Raising maintenance requirements in lift systems is critical for guaranteeing long term functional effectiveness and security. Regular maintenance not just boosts the efficiency of lift systems however likewise reduces the risk of unexpected breakdowns and makes certain the safety and security of customers. By adhering to strict maintenance methods, lift proprietors and operators can considerably reduce the likelihood of pricey fixings and downtime.

Carrying out a detailed maintenance schedule that includes regular assessments, lubrication of relocating components, and positive replacement of used components is important. Using innovative modern technologies like IoT sensors and predictive upkeep software can aid in keeping track of the lift's problem in real-time, allowing prompt interventions prior to problems rise. Furthermore, providing constant training for maintenance personnel on the latest market standards and finest practices is necessary for supporting upkeep excellence.

Moreover, fostering a culture of responsibility and focus to detail among maintenance groups can better elevate maintenance requirements. Urging open interaction channels for reporting and dealing with upkeep concerns quickly can assist in keeping a high degree of lift system integrity. Ultimately, by prioritizing and elevating maintenance requirements, lift systems can operate effectively and safely for a prolonged duration.

Final Thought

In verdict, reliable lift fixings call for aggressive upkeep approaches, repairing strategies, and boosted fixing abilities. By addressing why not try these out common challenges and elevating upkeep criteria, upkeep experts can efficiently guarantee the smooth operation of lifts - Lift Maintenance Repair. Implementing these Read More Here expert understandings can bring about boosted performance, lowered downtime, and raised safety and security for both guests and devices

In the realm of lift repair and maintenance, revealing the methods that lead to effective and efficient solution is akin to figuring out a complex problem.An additional common challenge in lift fixings is the lack of proper upkeep records. By taking on a positive method to upkeep, building supervisors and lift maintenance groups can attend to potential concerns before they rise right into costly fixings or downtime.In final thought, efficient lift fixings need proactive upkeep strategies, repairing techniques, and boosted repair work abilities. By dealing with usual difficulties and boosting maintenance standards, maintenance specialists can effectively ensure the smooth operation of lifts.

Report this page